Blog objectives

This blog describes the learning done during the first 18 months of the Israeli Food IoT consortium activities. It describes the unique problems that were identified while installing wireless sensors in the food production lines and the solutions and insights that were developed in order to adapt the generic IoT technology to the needs of the industry.

Although the CartaSense technology is proprietary, the problems and solutions described are generic in nature and can be of use by other food manufacturers.

Thanks

The following companies, participating in the Israeli Food IoT consortium, contributed to the document and were part of the work that was done over the 18 months of the first period of the consortium:

- 2 Fishermen – Fish processing

- Beth-El food – Confectionary products sold under the Aunt Berta brand

- Yehiam – Processed meat products

- Straus Nof Hagalil – Manufacturer of Chocolates and chocolate based sweets

- Hylabs – Tools for detection and identification of microorganisms molecular biology products

Preface

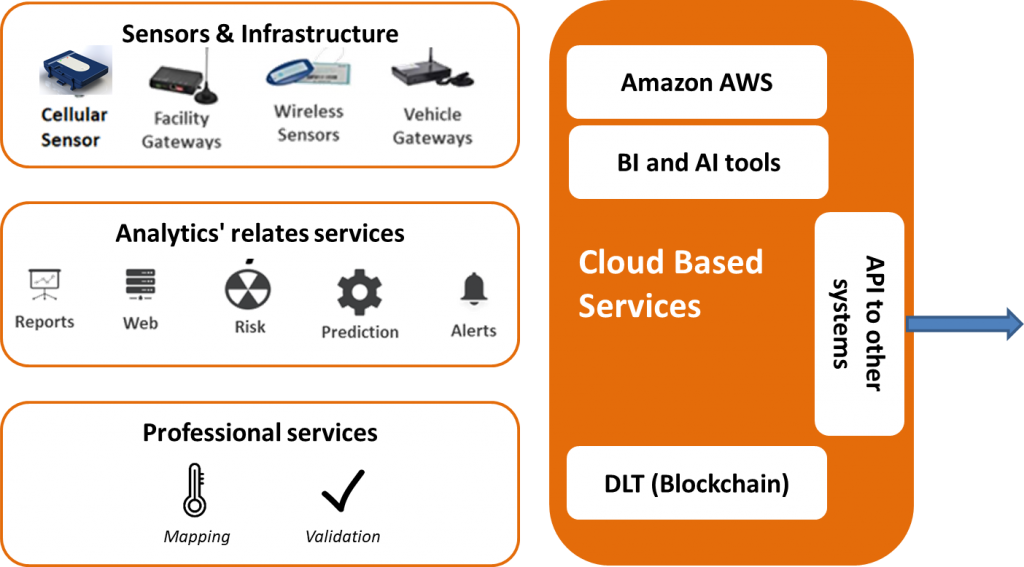

CartaSense is offering solutions based on wireless sensors that are connected via a Mesh network to wireless gateways connecting them to the cloud via cellular and/or Ethernet.

The company provides an end-to-end solution, including wireless sensors, gateways, cloud services, and additional services such as API enabling integration with customer systems.

The following diagram provides a system view of the CartaSense offering.

CartaSense wireless sensors have an internal power source enabling autonomous operation between 2 and 5 years without the need to replace the internal batteries.

The gateways require an external power source but have internal, rechargeable, batteries that enable continuous operation of up to 24 hours once external power is not available.

CartaSense systems were installed and tested in several companies of different types that mostly had the same problems. However, each one of those companies had unique issues that resulted from the uniqueness of this company.

- Two fishermen: a processor of fish products, packing and distributing them to other sites as well as having their, on-site, company shop.

- Bet-El foods: small factory manufacturing jam and other confectionery products. The initial work was done in the old site spread over 2 old buildings and a nearby greenhouse.

- Yehiam: A small to medium-size manufacturing meat-based products and is spread over 2 big old structure buildings.

- Straus Nof-Hagalil: A medium-size confectionary plant that combines both old and new technologies and is spread over several buildings and in some cases requires a low humidity environment.

- HY labs: contains many refrigerators working in a different range of temperature ranges reaching even -80 degrees.

Key problems identified

The first chapter of this blog briefly describes the key problems found during the first period of the Consortium. Each specific problem will be described in a follow-up chapter that will present also the possible solutions identified and the actual solution that was selected.

We don’t assume that the selected solutions are the only possible ones, but they do provide a wider viewpoint and optionally better tools when implementing a solution for other specific problems.

Installing equipment in production lines, and specifically for food products, is presenting problems of which some can be thought in advance and some can only be detected during the actual installation. The following list describes the key issues that were detected during installing equipment in the manufacturing lines.

- Availability of reliable power source for the sensors and gateways near the production lines

- Communication problems of the solution to the cloud

- Communication problems of wireless sensors

- Environmental problems such as high temperature, very high/low humidity, metal environment, and electronic interference.

For each of the above families of problems, the next chapters will offer a family of generic yet cost-effective solutions that can be implemented by a wide range of food manufacturers. A CartaSense solution, that was actually implemented, will also be presented as a real demonstration of the solution.